Talawade, Pune, Maharashtra

- GST NO. : 27AHOPD0404E1ZW

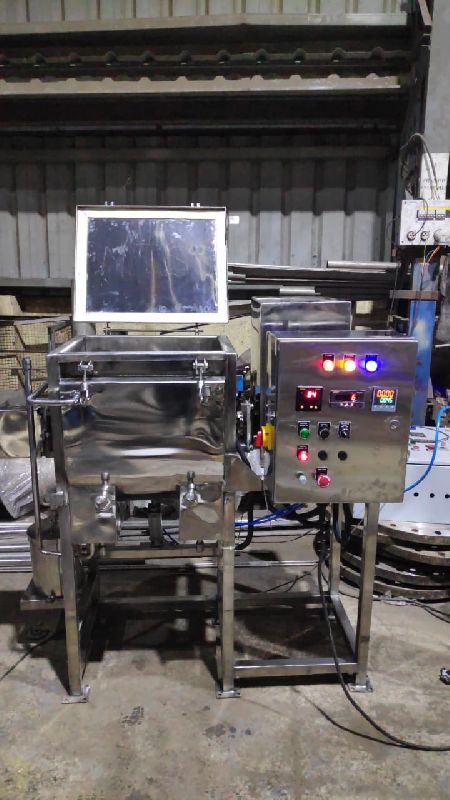

Industrial Blenders

In a Blender, a long complicated single paddle is mounted axially and used to disperse the ingredients of the mixture. The ribbon is usually so constructed that the powder near the outside of the container is moved in one direction, whereas in the middle it is moved in the opposite direction. Ribbon mixer are available from several manufacturers and they all have their own type of ribbon. The reader should note that many of the companies mentioned with respect to a particular type of mixer in the discussion often make other type of mixers, as set out in their catalogs.

INDUSTRIAL USE

Ribbon mixers are a basic industrial mixing tool. They consist, basically, of a trough-shaped casing (usually 2 to 3 times longer than it is wide) with a semicircular bottom, fitted with a horizontal longitudinal shaft on which are mounted arms supporting a combination of ribbon blades, paddles or helical screws set at a fairly close clearance to the semicircular mixer body so that no layer of material remains on the bottom of the mixer. The most effective design of ribbon layout is the double spiral in which the outer ribbon moves the product in one direction and the inner ribbon moves it in the opposite direction. This creates axial flow and prevents any buildup of material moved by the blades as they rotate is relatively small so that mixing times can be long. The capacity of the mixer should not be exceeded otherwise the ribbon and/or blades are not effective and the surface layers of the powder do not get adequately mixed.

- Ribbon mixers are normally operated at room temperature but they may be jacketed for steam heating (at atmospheric pressure)or water cooling, should this be called for .

- Although ribbon mixers are relatively standard in design there are many modifications and commercial design options available depending on:

- materials characteristics

- production requirements, particularly batch size and working conditions

machine characteristic such as loading and unloading facilities

One does not normally fill this type of mixer to more than 50% of the available volume. Normally the capacity of this type of mixer is restricted to an upper limit of 15 m.

Sometimes, to improve the dispersion of ingredients in ribbon mixers, the ribbon blades are built to be close to the cylindrical wall to give high shearing. Sometimes the ribbons are also fitted with rubber wipers to ensure complete intermingling of the ingredients by lifting any packed material near the wall into the middle of the ribbon ensemble. It is difficult to predict the scale-up performance if one attempts to increase mixing capacity by going to a larger mixer of the same type.

Type of Blenders we fabricate:

As per client process demand we fabricate, Ribbon Blenders, Double cone blender, Octazonal blender and Cone blender our customers are spared across the world.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Weight | 100Kg |

| Voltage | 220V |

| Usage | Laboratory Industry |

| Power Source | Electric |

| Warranty | 2 Year |

Preferred Buyer From

| Location | Anywhere in India |

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Voltage | 220V |

| Usage | Laboratory Industry |

| Power Source | Pneumatic |

| Automatic | Automatic |

| Finishing | Polished |

Preferred Buyer From

| Location | Anywhere in India |

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Weight | 100Kg |

| Voltage | 220V |

| Usage | Laboratory Industry |

| Material | SS |

| Power Source | Electric |

| Warranty | 2 Year |

Preferred Buyer From

| Location | Anywhere in India |

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Anywhere in India |

We are offering ribbon blenders, which are available in different speculations depend upon application. We are a renowned ribbon blender manufacturer, exporter, and supplier from india. Our ribbon blender is available with u-shaped horizontal trough and double helical ribbon for high speed and effective rotation. It blends powder in horizontally and vertically as well. Our ribbon blender is suitable for various cohesive powders and can easy handle different kind of densities. available in :

- liters : 100 to 5000

- material : stainless steels (varied grade)

- model : gmp (optional)

components :

- electrical motor

- worm reduction gear

- belt drive

- mixing stirrer

- discharge valve(centrally located) & top cover

- cooling or heating jacket( optional)

applications :

- industrial mixers

- pharmaceutical mixers

- industrial pharmaceutical mixers

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Anywhere in India |

We are a distinguished Octagonal Blender Manufacturer, Exporter, and Supplier in India. Our Octagonal Blender is used extensively in various industries like Pharmaceutical, Food processing, chemical, and cosmetic for blending and lubrication procedure of dry granules and powder equally. It is an ideal machine, as it does slow and gentle blending of granules, and guarantees best results in each attempt. Our Octagonal Blender is manufactured using SS 304 / SS 316 or SS 316 L quality material, as per the order placed by the clients. Its body structure and Safety guard system is fabricated using mild steel & coated in standard model and GMP Model is manufactured form SS 304 & polished in matt finish. Available In : Liters : 100 to 5000 Liters3 to 5 Liters for R & D models Features : Efficient performance Versatile blending machineEasy to clean and maintain Easy to operateSafe operation Easy to Load and unload material Economical High durable Components : Baffles Charging port Outlet with butterfly valveSturdy Stand Electric Motor and Gear BoxManual rotating facility along with hand wheel for inchingControl panel board Safety railing Optional : Contact parts construct as per SS316 Flameproof drive motor including flameproof starter. Vacuum loading option available for material chargingCylindrical container along with cone for material charging

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Anywhere in India |

Available In :

- Liters : 5 liters to 1500 liters

Features :

- Balanced cone to avoid excessive load

- Durable gearbox and Flameproof motor

- Easy to load and unload material

- Easy to clean and maintain

Used In :

- Pharmaceutical Industry

- Chemicals Industry

- Food Industry

- Fertilizers Industry

- Plastics Industry

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Anywhere in India |

Components :

- Cylindrical shell

- Two conical frustums

- Butterfly valve

- Robust stand with bearing blocks

- Gear box along with motor

- Control panel board

- Safety railing

Specifications :

- Manual rotating facility along with hand wheel for inching. The same facility is provided with SS cover & limit switch in 200 Kg and above model

- Available with Two nos. of safety rods at backside, option for left and right hand users

- One shaft with 04 nos. of fixed buffels with mirror polished provided inside the cone

- Polished cone polished with matt and mirror polish externally and internally

- All moving parts covered with SS304 covers

- Quality safety guard made SS304 pipes located in front of the m/c with limit switch

- Panel manufactured using SS304 material, available with facility of three-phase indication .i.e. D.O.L. Tarter, Digital Timer, and Amplify Meter

- Left side drive or with right side drive option as per the need

- Worm reduction gear for speed reduction in blender

- Food grade rubber gasket will be used on both ends of cone as well as in butterfly valve

- General body made up form of SS304 and finely polished to the matt / mirror finish as per the demand of the clients in GMP Model.

- Safety guards and covers fabricated of SS304 in GMP Model

- Hand wheel is available manual tilting of cone.